At PSM BrownCo, quality is more than just a word. We’re committed to excellence, and quality is the backbone of our business.

At PSM BrownCo, quality is more than just a word. We’re committed to excellence, and quality is the backbone of our business.

Our commitment to producing quality P/M parts and providing the best possible customer service is shared by everyone in our organization, from the newest person on the shop floor to the front office.

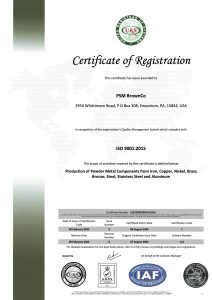

ISO 9001 Certified

PSM Brownco is an ISO 9001 certified company that utilizes advanced equipment and instrumentation to assure complete compliance to both dimensional and metallurgical specifications. Click image at left for large certificate (opens in new window).

Quality Control In Parts Production

Quality Control In Parts Production

Quality control is a major factor in parts production at PSM BrownCo. We regularly use independent testing facilities for quality control, and the tools and equipment we utilize to ensure that our customers recieve parts and components of the best quality include the following:

• Hardness Tester

• Magnaflux Crack Detection

• Apparent Density/Porosity Inspection Equipment

• Micro-View Optical Measuring System

• Dew Point Analysis

• In-House Bar Coding System

• Optical Comparator

• Complete set of plug gages

• Torque Testing equipment

• Tensile Strength and Compression Testing

• Micrometers including depth, inside and outside, with capacity .up to 6 inches